Tailored Tempering

The thermal printing technology first realized by our company allows the user to create different temperature zones in the same blank. To this end, the various regions are subjected to a selective localized heat treatment based on a differentiation of time-temperature curves.

Thus, in addition to the hard martensitic areas obtained by conventional press hardening, soft zones can be produced as well. What is more, our technology can provide exceptionally narrow transition areas of max. 30 mm between the different hardness zones.

On blanks leaving the press, distinct hardness levels are thus imparted to specified areas. Our customers in the automotive manufacturing and supplier industries derive numerous new options in the production of safety-relevant body parts from this technology, because different materials can also be joined together. In this way, profiles that are difficult to press and significantly lighter bodies can be produced.

Using our thermal printer, substantially lighter car bodies can be built – for more fuel efficient, eco-friendly cars.

Whatever part geometry or temper zone layout you need, we can build a custom-designed thermal printer for you that will perfectly match your individual schwartz heat treatment system.

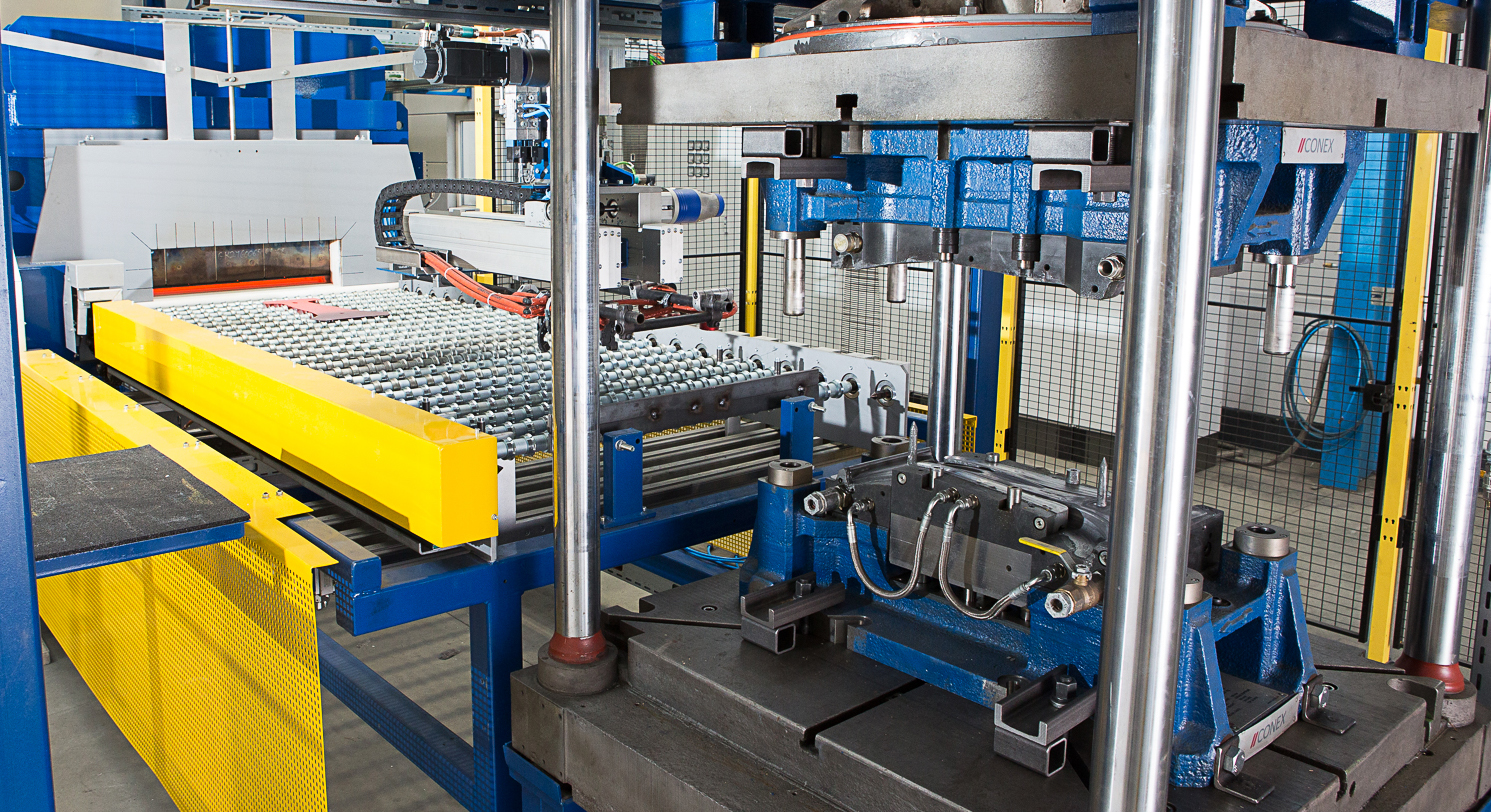

At our headquarters in Simmerath, we have set up a pilot line with the near-series “inline printer” for driving test parts. We use it to demonstrate to our customers in-house that the specifications of their components can be implemented using the new tailored tempering process.