Heat treatment systems for copper and copper alloys

In addition to our heat treatment systems for press hardening and for heat treating aluminum, we also supply systems for heat treating copper strips and coils as well as copper alloys in the nonferrous metals sector.

Products are heated to the desired temperature by convection. Depending on customer requirements, various hot-air or protective atmosphere flow management systems are implemented to ensure fast and uniform heating.

Our product line-up includes diverse design concepts such as continuous conveyor furnaces, chamber furnaces and roller heath furnaces.

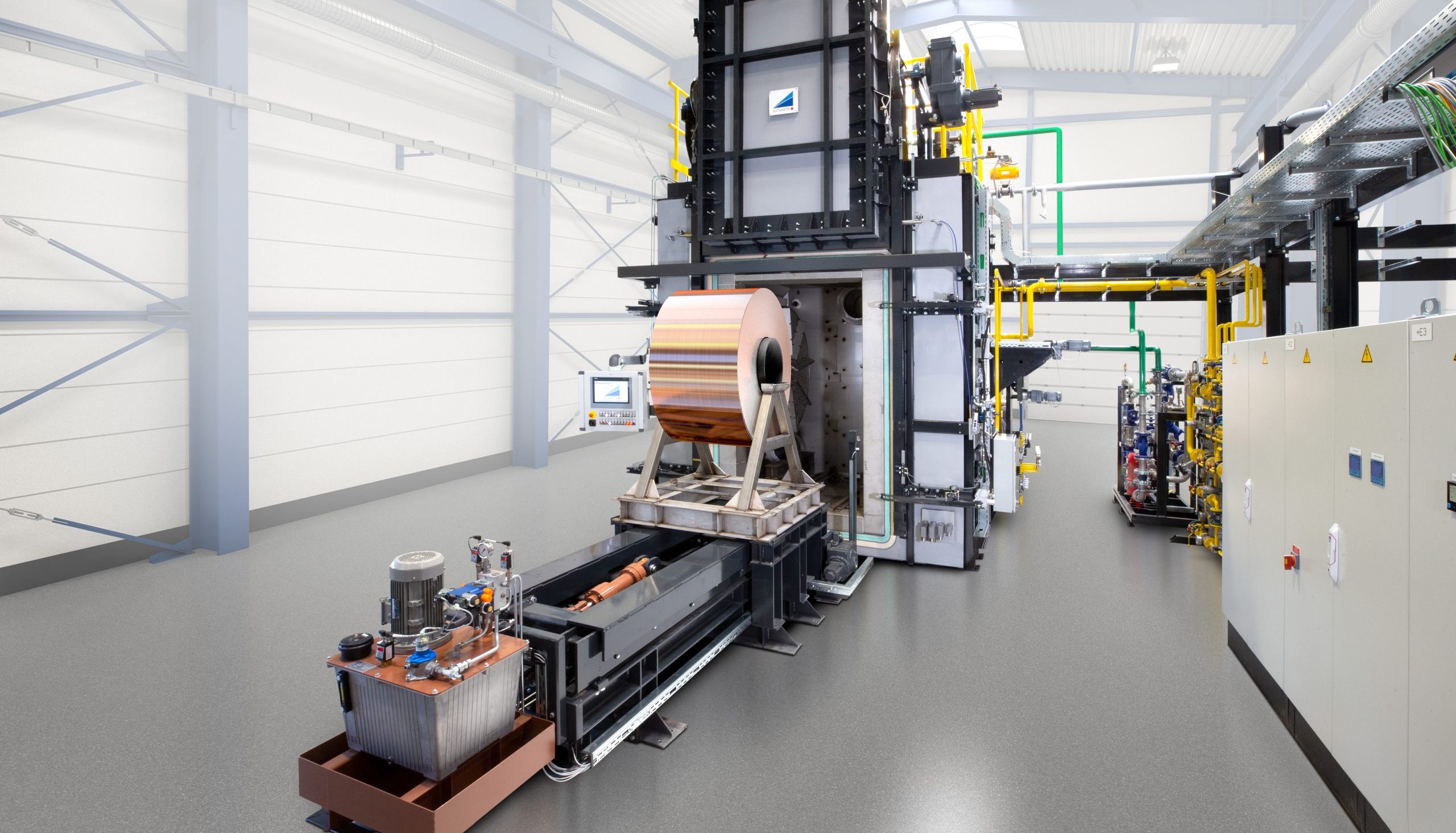

The schwartz product portfolio includes a newly developed chamber furnace with adjustable and rotating nozzle arrays for heat treating non-ferrous metal.

In this furnace, coils of copper and copper alloy strip can be heated and cooled quickly and uniformly without causing mechanical damage to any part of the surface. The maximum temperature difference reached is 10K.

The patented nozzle walls prevent hotspots and any rolling oil escaping from the coils can evaporate unhindered.

The heat treatment and cooling processes take place in an atmosphere comprising a mix of nitrogen and hydrogen. Despite using a low proportion of hydrogen (maximum 5 percent), dwell times are achieved which in other furnace systems are possible only with a much higher hydrogen concentration. This helps reduce operating costs. The furnace can be designed as a single-coil or multiple-coil system.

A safety concept for the furnace atmosphere and a simulation program for calculating the heat treatment, holding and cooling process are integrated into the system controls. The furnace with charging system is installed directly on the shop floor without the need for any complex foundation work.