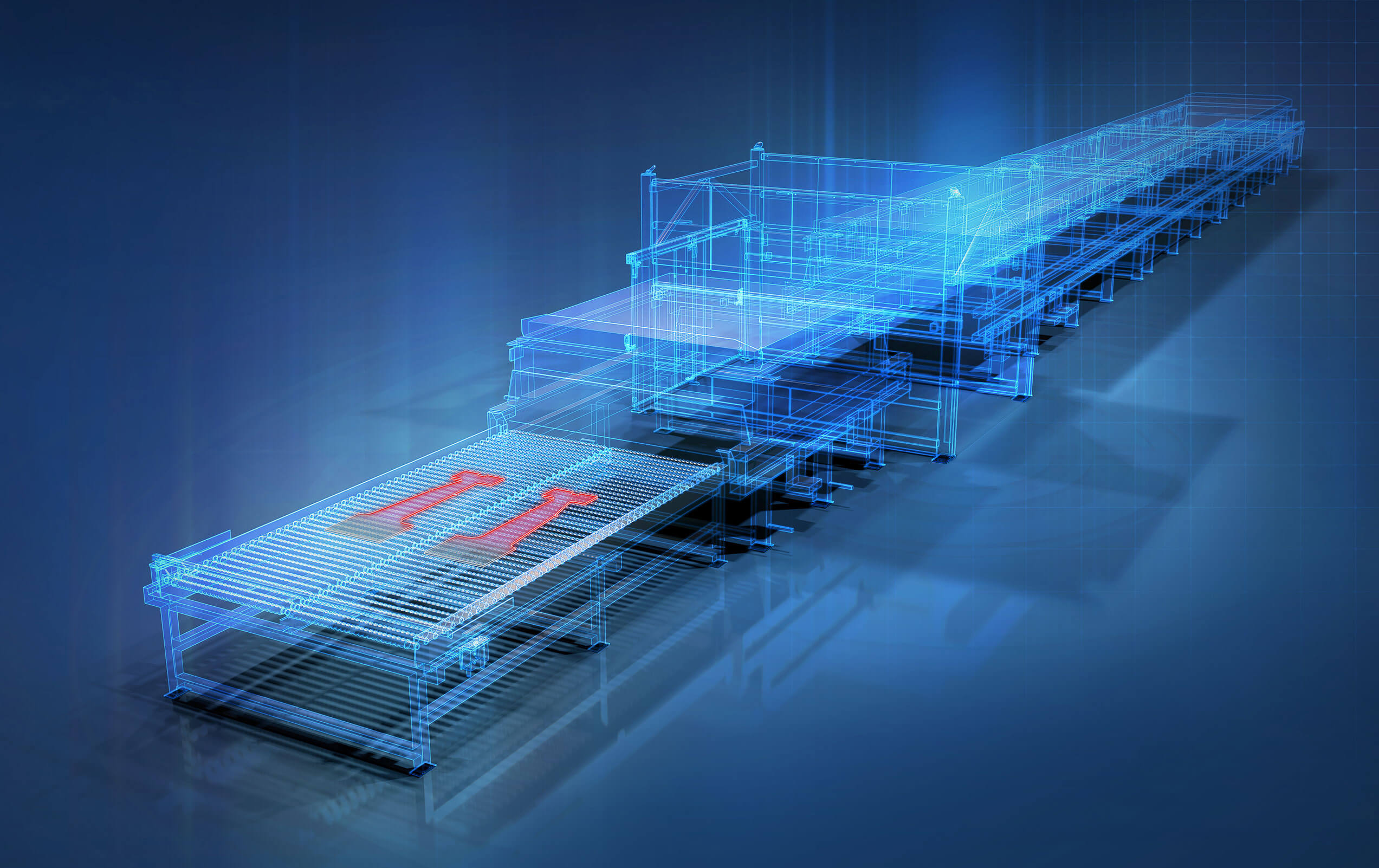

The patented thermal printing technology first established by our company allows the user to create two or more different temperature zones on the same blank. Each of these different sectors undergoes an individual, targeted, localized heat treatment and thus a locally altered time-temperature curve.

This allows for soft areas to be defined in addition to the hard martensitic areas covered by conventional press hardening. Our innovative technology enables both very narrow and larger transition areas between the different strength ranges, depending on individual requirements.

The different strength ranges resulting from the subsequent pressing of the blanks thus open up new possibilities for the automotive and supplier industry in the production of safety-relevant body components. In addition to a significant weight reduction, there are additional opportunities for the joining technology.

Consistent lightweight construction plays a central role in reducing fuel and energy consumption in automotive engineering.

Regardless of the particular component design, layout or specifications for the different strength ranges you require - we can customize the ideal inline thermal printer for your schwartz heat treatment system.