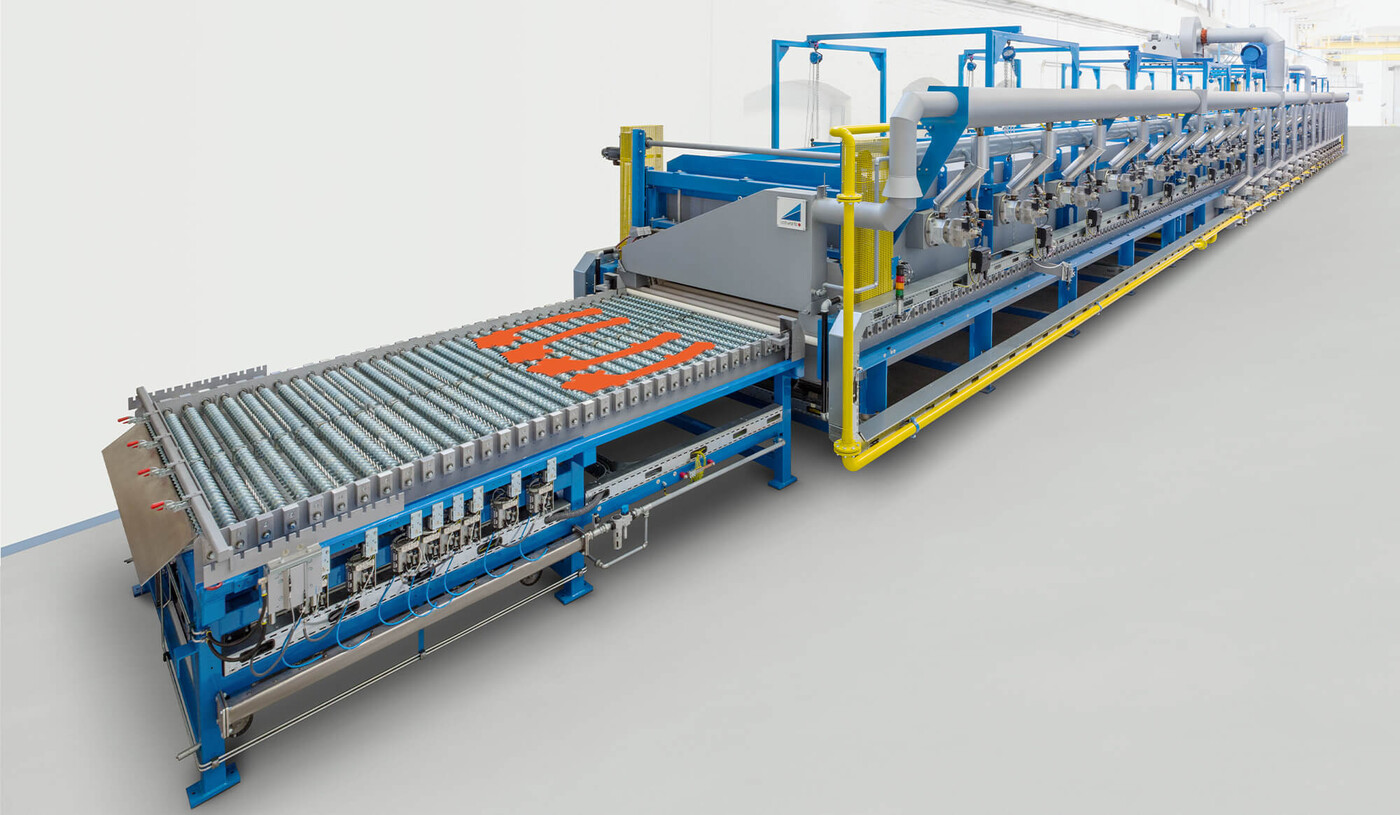

Heat treatment systems for press hardening

Enhancing vehicle safety, while cutting energy consumption and hence CO2 emissions through reduced weight – such are the challenges faced by the automotive industry today. To meet these demands, engineers rely on high-strength steels that are shaped into safety-relevant structural bodywork components – e.g., A or B pillars, side intrusion beams, or door frame reinforcements – by press hardening technology.

For this, we supply automotive manufacturers and their suppliers with the perfect heat treatment system, thereby helping them to build safer and more environmentally friendly vehicles.

To date, we have built and delivered around 450 roller hearth furnaces for our customers’ press hardening needs. In the press hardening segment we are the global market leader today.

Custom solutions for your success

Depending on the requirements for each specific application, our furnace systems are designed with indirect gas firing, electric heating, or hybrid heating technology. The heat treatment can take place in normal (air) atmosphere, protective atmosphere, or dried air atmosphere.

Vehicles with increased safety and reduced consumption

Modern auto body manufacturing would be difficult to imagine without heat-treated steel components. Indeed, the use of such parts is continuously growing.

Contact Sales

How can we support you?

schwartz GmbH

Edisonstrasse 5

52152 Simmerath

Germany