The challenge:

Manufacturing press-hardened car body parts requires high-temperature processes – and this is exactly what the HyHeat project is addressing. The aim being to move to climate-friendly fuel gases and to actively improve the CO₂ balance.

The solution:

Together with Forschungszentrum Jülich, we are developing a new process technology to help reduce emissions under the HyHeat research project. This project is part of the Helmholtz Hydrogen Cluster HC-H2.

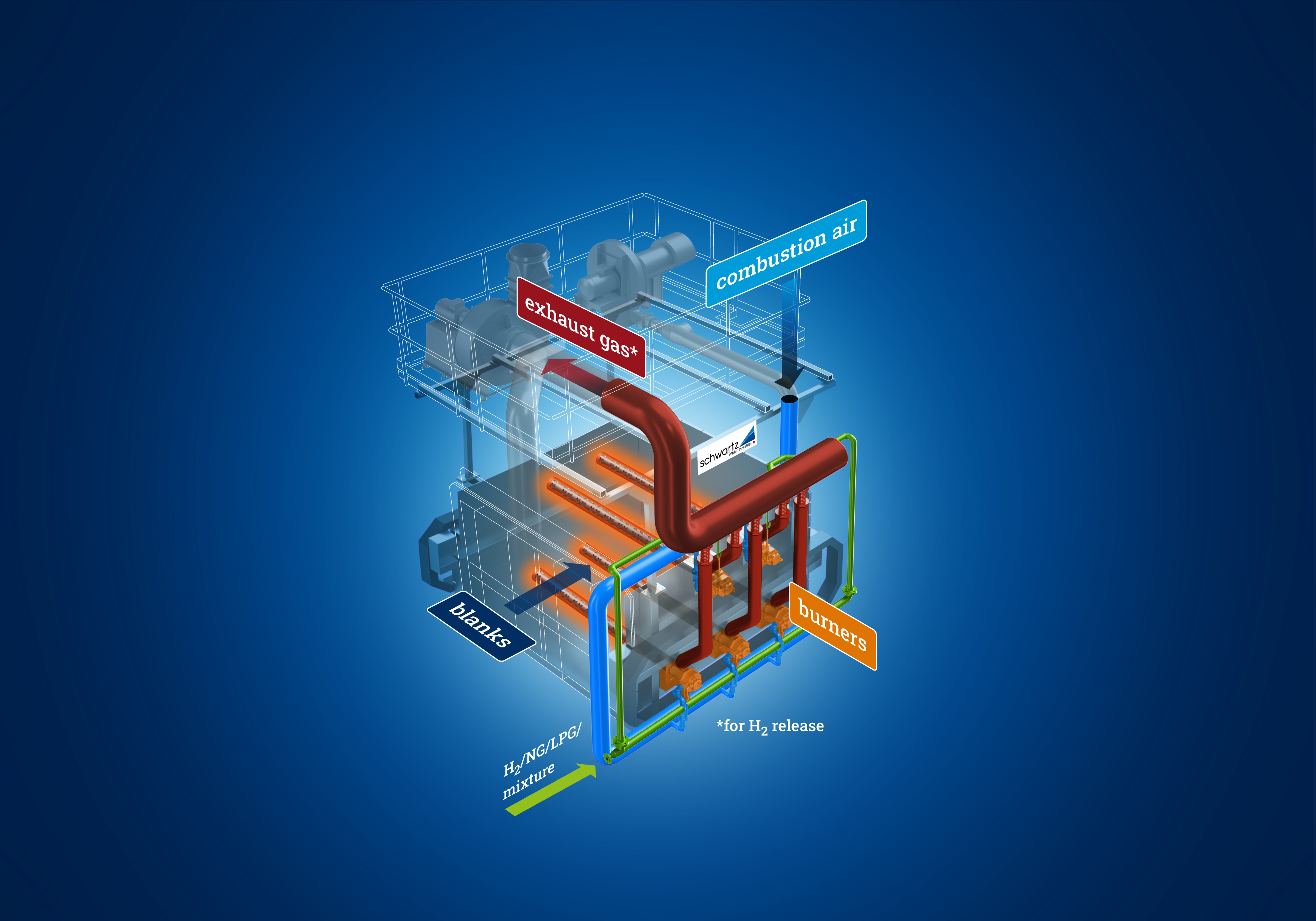

At its heart are innovative multi-fuel burners developed by our daughter Econova GmbH. These burners can run on hydrogen, natural gas and gas mixtures, combining high operational flexibility with constant power output.

Synergy effect:

In addition, waste heat from the equipment is used to release chemically absorbed hydrogen from a liquid organic hydrogen carrier – creating a clever link between process heat and hydrogen infrastructure.

HyHeat represents tomorrow’s climate-neutral production – a scalable, technology-neutral approach and one of the drivers of structural change in the Rhenish coal mining area.

The full article can be found here: HyHeat: Using Hydrogen for More Climate-Friendly Metal Processing

Foto © Forschungszentrum Jülich